Suspension polyvinyl chloride resin

Suspension polyvinyl chloride resin,

PVC SG5, PVC SG6, PVC SG8,

Suspension polyvinyl chloride resin

SG-1: K value 77-75 average degree of polymerization

SG-2: K value 74-73 average degree of polymerization

SG-3: K value 72-71 average degree of polymerization 1350-1250

SG-4: K value 70-69 average polymerization degree 1250-1150

SG-5: K value 68-66 Average polymerization degree 1100-1000

SG-6: K value 65-63 Average polymerization degree 950-850

SG-7: K value 62-60 average polymerization degree 850-750

SG-8: K value 59-55 Average polymerization degree 750-650

Main uses:

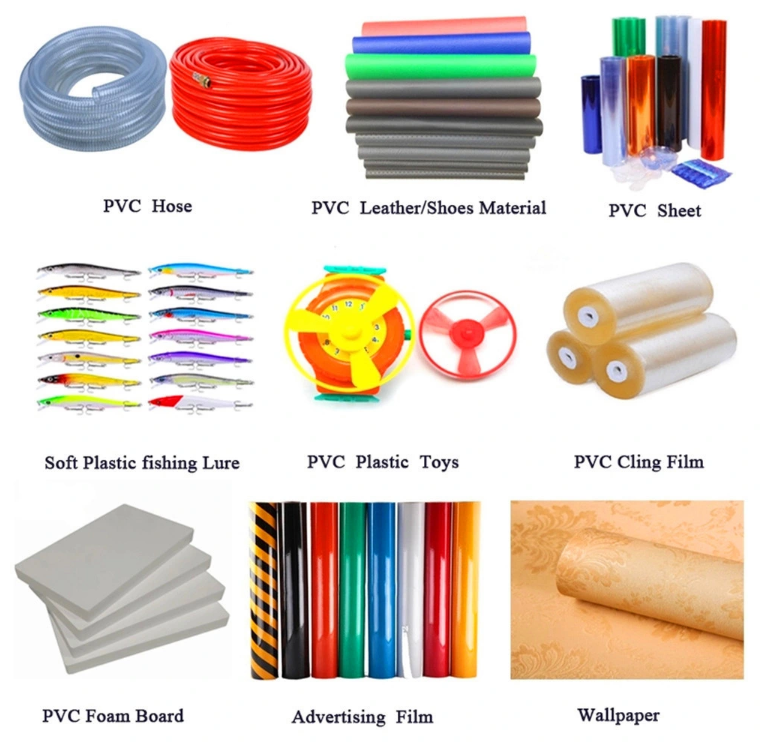

PVC resin can be processed into a variety of plastic products, according to its use can be divided into soft and hard products two categories, mainly used in the production of transparent sheets, pipe fittings, gold cards, blood transfusion equipment, soft, hard pipes, plates, doors and Windows, profiles, films, electrical insulation materials, cable sheathing, blood transfusion materials and so on.

1.PVC general soft and hard products – the use of extruder can be squeezed into soft and hard tubes, cables, wires, etc.;Using injection molding machine with various molds, can be made into plastic sandals, soles, slippers, toys, and other daily necessities and automobiles and electrical accessories.

2.PVC rigid pipe and profile – compared with other plastics, PVC has excellent aging resistance, high impact strength and toughness, low price, suitable for drainage pipes and other building pipes, and profile profiles.

3.PVC film – PVC and additives mixed, plasticized, using three or four roller calendering mechanism into a specified thickness of transparent or colored film, with this method of processing film, become calendering film.Can also be cut, heat processing packaging bags, raincoats, tablecloths, curtains, inflatable toys, etc.Wide transparent film can be used for greenhouses, plastic greenhouses and plastic mulch.Bidirectionally stretched film, the heat shrinkage property, can be used for shrink packaging.

4.PVC coated products – backed artificial leather is PVC mixed on cloth or paper, and then plasticized at more than 100 degrees Celsius.PVC and additives can also be rolled into a film, and then pressed together with the substrate.The artificial leather without substrate is directly rolled by the calender into a certain thickness of the soft sheet, and then pressed on the pattern.Artificial leather can be used to make suitcases, bags, book covers, sofas and car cushions, and floor leather, used as floor material for buildings.

5.PVC foam products – soft PVC mixing, add the right amount of foaming agent to do sheet material, foam molding for foam plastic, can be used as foam slippers, sandals, insole, and shock-proof buffer packaging material.Can also be extruder based into low foaming hard PVC plate and profile, can replace wood trial, is a new type of building materials.

6.PVC transparent sheet — PVC plus impact modifier and stabilizer, after mixing, plasticizing, calendering and become transparent sheet.Thermoforming can be made into thin wall transparent container or used for vacuum blister packaging. It is an excellent packaging and decoration material.

7 PVC hard plate and plate – PVC add stabilizer, lubricant and filler, after mixing, extruder can extrude a variety of caliber of hard pipe, shaped pipe, bellows, used as down pipe, water pipe, wire sleeve or stair handrail.Hard sheets of various thickness can be made by hot pressing the laminated sheets.The sheet can be cut into the desired shape, and then PVC welding rod is used to weld into a variety of chemical corrosion resistant storage tanks, air ducts and containers with hot air.

8.PVC other – doors and Windows are assembled with hard special-shaped materials.In some countries, it has occupied the market of doors and Windows with wood doors and aluminum Windows;Imitation wood materials, generation of steel building materials (north, seaside);Hollow container.

Product detail

PVC is an acronym for polyvinyl chloride. A resin is a material often used in the production of plastics and rubbers. PVC resin is a white powder commonly used to produce thermoplastics. It is a synthetic material widely used in the world today. Polyvinyl chloride resin has outstanding characteristics such as abundant raw materials, mature manufacturing technology, low price, and wide range of uses. It is easy to process and can be processed by molding, laminating, injection molding, extrusion, calendering, blow molding and other methods. With good physical and chemical properties, it is widely used in industry, construction, agriculture, daily life, packaging, electricity, public utilities, and other fields. PVC resins generally have high chemical resistance. It is very strong and resistant to water and abrasion. Polyvinyl chloride resin (PVC) can be processed into various plastic products. PVC is a lightweight, inexpensive, and environmentally friendly plastics.

Features

PVC is one of the most widely used thermoplastic resins. It can be used to make products with high hardness and strength, such as pipes and fittings, profiled doors, windows and packaging sheets. It can also make soft products, such as films, sheets, electrical wires and cables, floorboards and synthetic leather, by addition of plasticizers

Parameters

| Grades | QS-650 | S-700 | S-800 | S-1000 | QS-800F | QS-1000F | QS-1050P | |

| Average polymerization degree | 600-700 | 650-750 | 750-850 | 970-1070 | 600-700 | 950-1050 | 1000-1100 | |

| Apparent density, g/ml | 0.53-0.60 | 0.52-0.62 | 0.53-0.61 | 0.48-0.58 | 0.53-0.60 | ≥0.49 | 0.51-0.57 | |

| Volatiles content (water included), %, ≤ | 0.4 | 0.30 | 0.20 | 0.30 | 0.40 | 0.3 | 0.3 | |

| Plasticizer absorption of 100g resin, g, ≥ | 15 | 14 | 16 | 20 | 15 | 24 | 21 | |

| VCM residual, mg/kg ≤ | 5 | 5 | 3 | 5 | 5 | 5 | 5 | |

| Screenings % | 0.025 mm mesh % ≤ | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.063m mesh % ≥ | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Fish eye number, No./400cm2, ≤ | 30 | 30 | 20 | 20 | 30 | 20 | 20 | |

| Number of impurity particles, No., ≤ | 20 | 20 | 16 | 16 | 20 | 16 | 16 | |

| Whiteness (160ºC, 10 minutes later), %, ≥ | 78 | 75 | 75 | 78 | 78 | 80 | 80 | |

| Applications | Injection Molding Materials, Pipes Materials, Calendering Materials, Rigid Foaming Profiles, Building Sheet Extrusion Rigid Profile | Half-rigid Sheet, Plates, Floor Materials, Linning Epidural, Parts of Electric Devices, Automotive Parts | Transparent film, packageing, cardboard,cabinets and floors, toy, bottles and containers | Sheets, Artificial Leathers, Pipes Materials, Profiles, Bellows, Cable Protective Pipes, Packaging Films | Extrusion Materials, Electric Wires, Cable Materials, Soft Films and Plates | Sheets, Calendering Materials, Pipes Calendering Tools, Insulating Materials of Wires and Cables | Irrigation Pipes, Drinking Water Tubes, Foam-core Pipes, Sewer Pipes, Wire Pipes, Rigid Profiles | |

Packaging

(1) Packing : 25kg net/pp bag, or kraft paper bag .

(2) Loading quantity : 680Bags/20′container, 17MT/20′container .

(3) Loading quantity : 1120Bags/40′container, 28MT/40′container .