Raw materials for producing PVC pipes

Raw materials for producing PVC pipes,

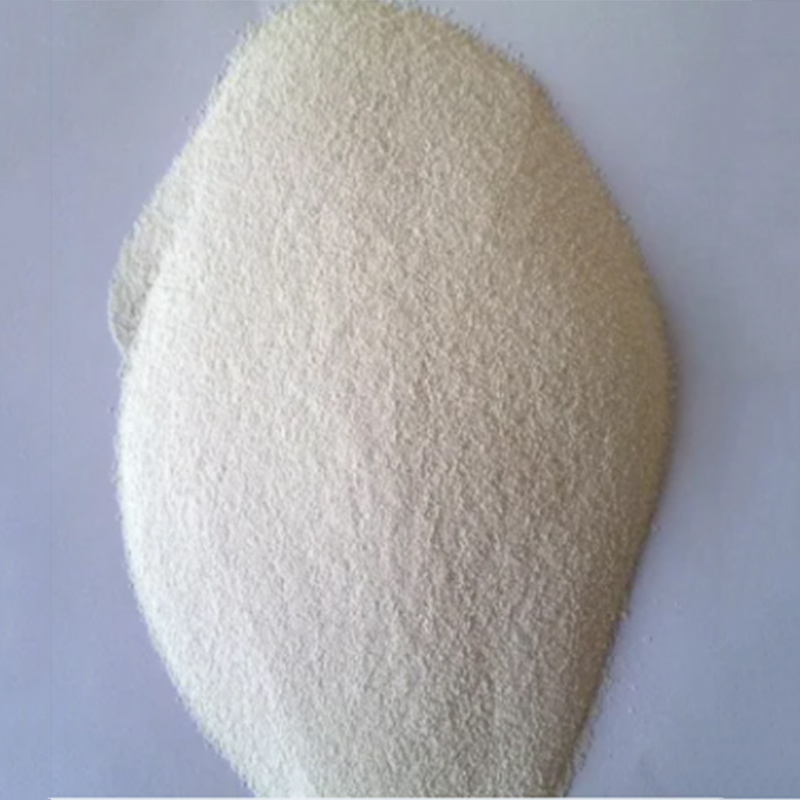

PVC Resin, PVC to produce pipe,

S-1000 polyvinyl chloride resin is produced by suspension polymerization process using vinyl chloride monomer as raw material. It is a kind of polymer compound with a relative density of 1.35 ~ 1.40. Its melting point is about 70 ~ 85℃. Poor thermal stability and light resistance, over 100℃ or long time under the sun hydrogen chloride begins to decompose, plastic manufacturing needs to add stabilizers. The product should be stored in a dry and ventilated warehouse. According to the amount of plasticizer, the plastic softness can be adjusted, and the paste resin can be obtained by emulsion polymerization.

Grade S-1000 can be used to produce soft film, sheet, manmade leather, piping, shaped bar, bellow, cable protection piping, packing film, sole and other soft sundry goods.

Parameters

| Grade | PVC S-1000 | Remarks | ||

| Item | Guarantee value | Test method | ||

| Average polymerization degree | 970-1070 | GB/T 5761,Appendix A | K value 65-67 | |

| Apparent density, g/ml | 0.48-0.58 | Q/SH3055.77-2006, Appendix B | ||

| Volatiles content (water included), %, ≤ | 0.30 | Q/SH3055.77-2006, Appendix C | ||

| Plasticiser absorption of 100g resin, g, ≥ | 20 | Q/SH3055.77-2006, Appendix D | ||

| VCM residue, mg/kg ≤ | 5 | GB/T 4615-1987 | ||

| Screenings % | 2.0 | 2.0 | Method 1: GB/T 5761, Appendix B Method 2: Q/SH3055.77-2006, Appendix A |

|

| 95 | 95 | |||

| Fisheye number, No./400cm2, ≤ | 20 | Q/SH3055.77-2006, Appendix E | ||

| Number of impurity particles, No., ≤ | 16 | GB/T 9348-1988 | ||

| Whiteness (160ºC, 10minutes later), %, ≥ | 78 | GB/T 15595-95 | ||

PVC pipes are manufactured by extrusion of raw material PVC, and generally follow the same steps of typical pipe extrusion operations:

1.Feeding of raw material powder called resin and filler into the PVC twin screw extruder;

2. Melting and heating in multiple extruder zones;

3. Extruding through a die to shape into a pipe;

4.Cooling of the shaped pipe (by spraying water on the pipe); and

5. Cutting of PVC pipes to the desired length.

The raw materials for producing PVC pipes are resin and filler (mainly calcium carbonate, or commonly known as stones). The standard mix is 1 kilogram (kg) of resin with 1 kilogram of filler. The production processes are mostly automated, with workers feeding the raw materials at the beginning of the process, monitoring the temperature in the process and checking the final product for any obvious defects before packing and dispatching to customers. All workers are trained and are capable of doing all these tasks competently. The main material for the manufacturing of PVC pipes is a powdery material called PVC resin.