PVC suspension resin for manufacturing PVC pipes & fittings

PVC suspension resin for manufacturing PVC pipes & fittings,

PVC suspention resin to produce PVC pipes and fittings,

PVC pipe (divided into PVC-U pipe, PVC-M pipe and PVC-O pipe) hard polyvinyl chloride pipe, is made of PVC resin with stabilizer, lubricant and other hot pressing extrusion molding, is the first to be developed and applied plastic pipe.

PVC-U pipe has strong corrosion resistance, easy bonding, low price and hard texture, but due to the seepage of PVC-U monomer and additives, it is only suitable for the water supply system where the transport temperature does not exceed 45 ° C. Plastic pipes are used for applications in drainage, wastewater, chemicals, heating fluids and coolants, food, ultra-pure liquids, mud, gases, compressed air and vacuum systems.

Pvc-o pipe, Chinese name biaxial oriented polyvinyl chloride, is the latest form of evolution of PVC pipe, through the special orientation processing process to manufacture the pipe, the PVC-U pipe produced by extrusion method for axial stretching and radial stretching, so that the PVC long chain molecules in the pipe in the biaxial arrangement, A new PVC pipe with high strength, high toughness, high impact resistance and fatigue resistance was obtained.

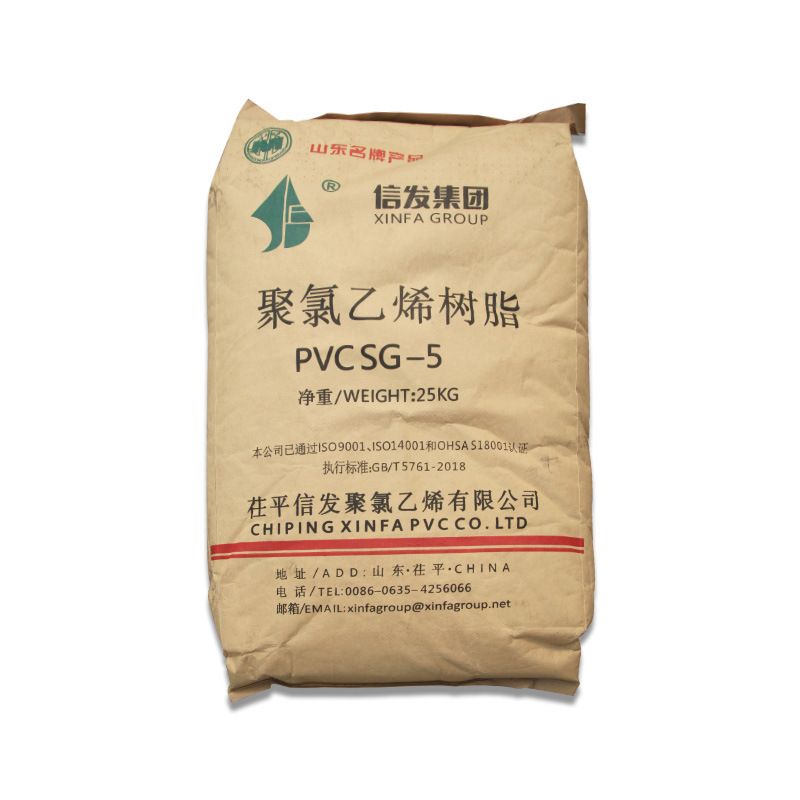

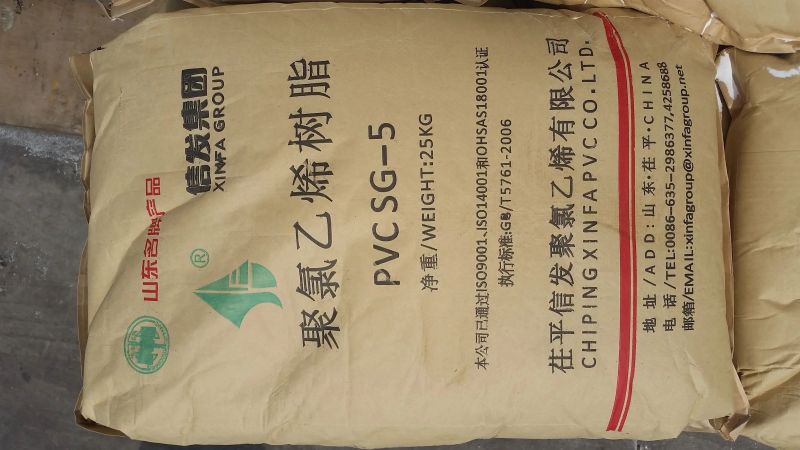

Product detail

PVC comes in two basic forms: rigid and flexible. Hard forms of PVC can be used in pipes, doors and Windows. It can also be used in bottles, other non-food packaging, and bank or membership cards. It can also be made into a soft finished product, which is made more flexible by the addition of plasticizers, most commonly phthalates. In this form, it can be used in soft piping, cable insulators, imitation leather, soft signage, inflatable products, and in many applications instead of rubber.

Polyvinyl chloride can be made from ethylene, chlorine and catalyst by substitution reaction. Due to its fire resistance and heat resistance, PVC is widely used in all walks of life and a variety of products: Wire skin, optical fiber skin, shoes, handbags, bags, ornaments, signs and billboards, architectural decoration supplies, furniture, hanging ornaments, rollers, pipes, toys (such as the famous Italian "Rody" jumping horse), animation figures, door curtains, rolling doors, auxiliary medical supplies, gloves, some food paper, some fashion, etc.

The PVC SG5 resin produced by suspension method is suitable for the production of rigid PVC pipes and profiles

Specification

|

Items |

SG5 |

|

Average degree of polymerization |

980-1080 |

|

K value |

66-68 |

|

Viscosity |

107-118 |

|

Foreign Particle |

16max |

|

Volatile Matter, % |

30max |

|

Apparent Density, g/ml |

0.48min |

|

0.25mm Sieve Retained, % |

1.0max |

|

0.063mm Sieve Retained, % |

95min |

|

No. of Grain/400cm2 |

10max |

|

Plasticizer absorption of 100g resin, g |

25min |

|

WHITENESS DEGREE 160ºC 10min, % |

80 |

|

RESIDUAL CHLORE THYLENE CONTENT, mg/kg |

1 |

Application

Piping, hard transparent plate. Film and sheeting, photograph records. PVC fibers, plastics blowing, electric insulating materials:

1) Construction material: Piping, sheeting, windows and door.

2) Packing material

3) Electronical material: Cable, wire, tape, bolt

4) Furniture: Decorate material

5) Other: Car material, medical appliance

6) Transportation and storage

4. Package:

25kg kraft paper bags lined with PP-woven bags or1000kg jambo bags

28 tons/40GP