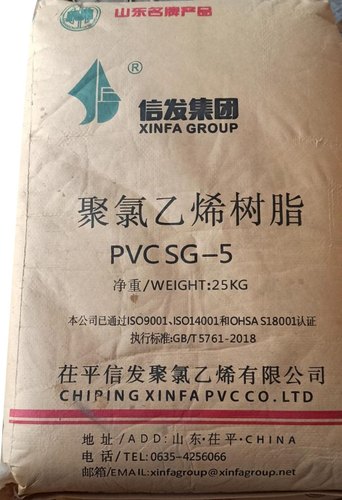

PVC SG-5 to produce pipe

PVC SG-5 to produce pipe,

PVC pipe production raw material,

In the production of hard tubes, SG-5 resin with low polymerization degree should be selected. The higher the polymerization degree, the better its physical and mechanical properties and heat resistance, but the poor fluidity of the resin brings certain difficulties to the processing, so SG-5 resin with a viscosity of (1.7~1.8) ×10-3Pa•s is generally selected.

Hard pipe generally uses lead stabilizer, its thermal stability is good, commonly used tribasic lead, but its own lubrication is poor, usually and good lubricity of lead, barium soap.

Processing of hard tubes, the choice and use of lubricants is very important, not only to consider the internal lubrication to reduce the intermolecular force, so that the melt viscosity decline conducive to forming, but also to consider the external lubrication, to prevent the melt and hot metal adhesion, so that the surface of the product bright.

Metal soap is generally used for internal lubrication, and low melting point wax is used for external lubrication.

The filler mainly uses calcium carbonate and barium (barite powder), calcium carbonate makes the surface performance of the pipe good, barium can improve the formability, make the pipe easy to shape, both can reduce the cost, but the amount of too much will affect the performance of the pipe, the pressure pipe and corrosion resistant pipe is best not to add or add less filler.

PVC resin products are usually white powder, calcium carbide SG-5 type PVC resin K value in 66-68, mainly used for extrusion pipe, profile, bar, sheet and other hard PVC products, the degree of polymerization in about 1000, large molecular weight.A variety of hard, soft and transparent products can be made by adding appropriate plasticizer in PVC resin.

Clean and covered vehicles should be used to prevent rain during product transportation. Storage, should be stored in a dry, well-ventilated warehouse.

Parameters

|

Items |

SG5 |

|

Average degree of polymerization |

980-1080 |

|

K value |

66-68 |

|

Viscosity |

107-118 |

|

Foreign Particle |

16max |

|

Volatile Matter, % |

30max |

|

Apparent Density, g/ml |

0.48min |

|

0.25mm Sieve Retained, % |

1.0max |

|

0.063mm Sieve Retained, % |

95min |

|

No. of Grain/400cm2 |

10max |

|

Plasticizer absorption of 100g resin, g |

25min |

|

WHITENESS DEGREE 160ºC 10min, % |

80 |

|

RESIDUAL CHLORE THYLENE CONTENT, mg/kg |

1 |

Application

Piping, hard transparent plate. Film and sheeting, photograph records.

1) Construction material: Piping, sheeting, windows and door.

2) Packing material

3) Furniture: Decorate material

Packaging

25kg kraft paper bags lined with PP-woven bags or 1000kg jambo bags

17 tons/20GP, 28 tons/40GP

Delivery time and method

1) Delivery shall be made within 7 working days upon receipt of advance payment.

2) Automobile transportation and shipping.

About us

Zibo Junhai Chemical Co., Ltd. is an integrated polymer resin manufacture and exporter in Shandong, China. We offer a full array of plastics resins: polyvinyl chloride (PVC), High Density Polyethylene (HDPE), Low Density Polyethylene(LDPE) , polypropylene (PP).

As a plastic raw material supplier in China, with more than 15 years experience in polymer resin, we have supply products and service to more than 200 hundreds customers in more than 30 countries all over the world at competitive prices and short delivery time.