PVC resin for wood plastic extrusion

PVC resin for wood plastic extrusion,

PVC CIF India, PVC K67, PVC Resin for extrusion,

Product detail

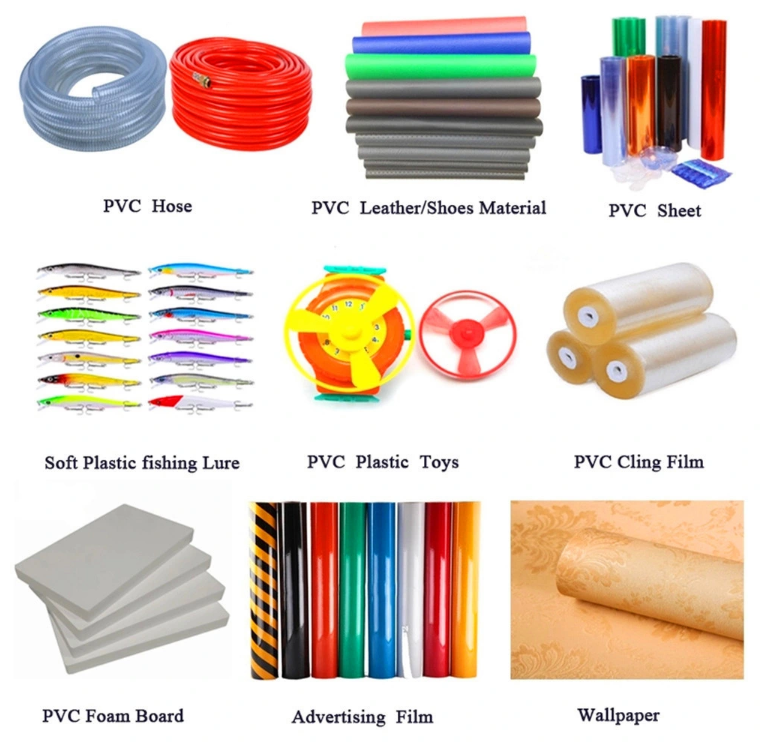

PVC is an acronym for polyvinyl chloride. A resin is a material often used in the production of plastics and rubbers. PVC resin is a white powder commonly used to produce thermoplastics. It is a synthetic material widely used in the world today. Polyvinyl chloride resin has outstanding characteristics such as abundant raw materials, mature manufacturing technology, low price, and wide range of uses. It is easy to process and can be processed by molding, laminating, injection molding, extrusion, calendering, blow molding and other methods. With good physical and chemical properties, it is widely used in industry, construction, agriculture, daily life, packaging, electricity, public utilities, and other fields. PVC resins generally have high chemical resistance. It is very strong and resistant to water and abrasion. Polyvinyl chloride resin (PVC) can be processed into various plastic products. PVC is a lightweight, inexpensive, and environmentally friendly plastics.

Features

PVC is one of the most widely used thermoplastic resins. It can be used to make products with high hardness and strength, such as pipes and fittings, profiled doors, windows and packaging sheets. It can also make soft products, such as films, sheets, electrical wires and cables, floorboards and synthetic leather, by addition of plasticizers

Parameters

| Grades | QS-650 | S-700 | S-800 | S-1000 | QS-800F | QS-1000F | QS-1050P | |

| Average polymerization degree | 600-700 | 650-750 | 750-850 | 970-1070 | 600-700 | 950-1050 | 1000-1100 | |

| Apparent density, g/ml | 0.53-0.60 | 0.52-0.62 | 0.53-0.61 | 0.48-0.58 | 0.53-0.60 | ≥0.49 | 0.51-0.57 | |

| Volatiles content (water included), %, ≤ | 0.4 | 0.30 | 0.20 | 0.30 | 0.40 | 0.3 | 0.3 | |

| Plasticizer absorption of 100g resin, g, ≥ | 15 | 14 | 16 | 20 | 15 | 24 | 21 | |

| VCM residual, mg/kg ≤ | 5 | 5 | 3 | 5 | 5 | 5 | 5 | |

| Screenings % | 0.025 mm mesh % ≤ | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 0.063m mesh % ≥ | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |

| Fish eye number, No./400cm2, ≤ | 30 | 30 | 20 | 20 | 30 | 20 | 20 | |

| Number of impurity particles, No., ≤ | 20 | 20 | 16 | 16 | 20 | 16 | 16 | |

| Whiteness (160ºC, 10 minutes later), %, ≥ | 78 | 75 | 75 | 78 | 78 | 80 | 80 | |

| Applications | Injection Molding Materials, Pipes Materials, Calendering Materials, Rigid Foaming Profiles, Building Sheet Extrusion Rigid Profile | Half-rigid Sheet, Plates, Floor Materials, Linning Epidural, Parts of Electric Devices, Automotive Parts | Transparent film, packageing, cardboard,cabinets and floors, toy, bottles and containers | Sheets, Artificial Leathers, Pipes Materials, Profiles, Bellows, Cable Protective Pipes, Packaging Films | Extrusion Materials, Electric Wires, Cable Materials, Soft Films and Plates | Sheets, Calendering Materials, Pipes Calendering Tools, Insulating Materials of Wires and Cables | Irrigation Pipes, Drinking Water Tubes, Foam-core Pipes, Sewer Pipes, Wire Pipes, Rigid Profiles | |

Application

Packaging

(1) Packing : 25kg net/pp bag, or kraft paper bag .

(2) Loading quantity : 680Bags/20′container, 17MT/20′container .

(3) Loading quantity : 1000Bags/40′container, 25MT/40′container .Formulation determination

Formula design is based on product performance, raw and auxiliary materials, molding process and equipment.This is a complicated and tedious work, in order to be safe, usually only on the basis of the original mature formula according to the experience of small reforms, and then through the test to determine the best solution that meets the requirements.The author is based on the formula of ordinary PVC doors and Windows profiles, adding wood powder, foaming agent, foaming agent, coloring agent, and then according to the orthogonal test to determine the amount of different raw and auxiliary materials.

The addition of wood flour will generally make the flow property of the material worse.With the increase of the content of wood powder, the plasticizing time is extended, and the fluidity will be lower and lower.If the fluidity of the material is too poor, the wood powder will be subjected to greater shear force, increase the residence time in the extruder, so that the wood powder is easy to burn, not conducive to extrusion;Conversely, if the liquidity is too large to form enough extrusion pressure, it will also cause strength defects and surface defects of products.Therefore, in the extrusion process, the rheological properties of the system have a great impact on the machining process and the properties of the final product.Table 2 shows the processing properties of composites with different wood meal contents.

Due to the large particle size and small density of the wood powder used in the test, the volume ratio of the wood powder filler in the system increases with the increase of the filling amount, and the adsorption capacity of the lubricant, plasticizer and processing additives is large.Although the processing process can produce large friction heat to speed up the plasticizer, but not enough to offset due to plasticizer, processing additives and other adsorbed plasticizer speed to slow down the impact of plasticizer time, so that the plasticizer delay.The larger the content of wood flour, the more processing AIDS absorbed, which will increase the plasticizing time, the poorer the processing performance.The final determination of the selection of wood powder content of 30.

Other raw materials used are 100 parts PVC, 3 parts tribasic lead sulfate, 1.5 parts dibasic lead sulfate, 0.5 parts lead stearate, 0.4 parts calcium stearate, 0.8 parts stearate, polyethylene wax..3 PCS, acrylic cool copolymer 5 PCS, chlorinated polyethylene 6 PCS, CaCO30 PCS, AC foaming agent 0.9 PCS, ACR-530 5 PCS, iron yellow 0.31 PCS, iron brown 0.15 PCS.