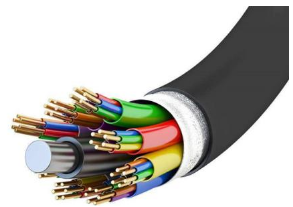

PVC resin for electrical protective sleeve

PVC resin for electrical protective sleeve,

PVC Cable Grade, PVC For Electric Wires, Suspension PVC resin,

Flame retardant PVC threading pipe refers to the PVC resin as the main raw material, adding other additives extrusion molding for electric wire and cable protection in industrial and architectural engineering below 1000V. Due to its light weight, flame retardant, good insulation, convenient installation and use, health, no pollution, low price, long service life and other advantages, in recent years, it has been widely used in the home interior decoration and construction engineering hydropower installation of pipe protection.

Hard POLYvinyl chloride (PVC-U) insulated electrical casing has light, medium and heavy three models, 6 specifications, respectively suitable for different applications. The light pipe is suitable for bright compress, and the medium and heavy pipe can bear the pressure above 750N and 1250N respectively. Therefore, it can be installed openly or in the dark in all kinds of concrete without cracking due to compression. At the same time, considering the particularity of the use of the product, flame retardant is added in the formula, so as to ensure the safety and reliability of the product in the use process. The product itself does not contain any plasticizer, so there is no hidden danger of attracting insects and rodents due to its special smell.

Features thermo plasticity, being insoluble into water, gasoline and alcohol, swelled or dissolved into ether, ketone, chlorinated aliphatic hydrocarbons, and aromatic hydrocarbon, high resistance to corrosion, and good dielectric property.

Specification

|

Type |

SG3 |

SG4 |

SG5 |

SG6 |

SG7 |

SG8 |

|

K value |

72-71 |

70-69 |

68-66 |

65-63 |

62-60 |

59-55 |

|

Viscosity, ml/g |

135-127 |

126-119 |

118-107 |

106-96 |

95-87 |

86-73 |

|

Average polymerization |

1350-1250 |

1250-1150 |

1100-1000 |

950-850 |

950-850 |

750-650 |

|

Number of impurity particle max |

30 |

30 |

30 |

30 |

40 |

40 |

|

Volatiles content % max |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

|

Appearing density g/ml min |

0.42 |

0.42 |

0.42 |

0.45 |

0.45 |

0.45 |

|

Residual after sieve 0.25mm mesh max |

2 |

2 |

2 |

2 |

2 |

2 |

|

0.063mm min |

90 |

90 |

90 |

90 |

90 |

90 |

|

Number of grain/10000px2 max |

40 |

40 |

40 |

40 |

40 |

40 |

|

Plasticizer absorbency value of 100g resin |

25 |

22 |

19 |

16 |

14 |

14 |

|

Whiteness % min |

74 |

74 |

74 |

74 |

70 |

70 |

|

Residual chlorethylenecontent mg/kg max |

5 |

5 |

5 |

5 |

5 |

5 |

|

Ethylidene chloride mg/kg max |

150 |

150 |

150 |

150 |

150 |

150 |

Applications

*SG-1is used in producing high-grade electrical insulating material

*SG-2is used in producing electrical insulating material, common soft products andfilm

*SG-3 is used in producing electrical insulatingmaterials, agricultural film, daily-use plastic products,such

as Films, raincoat, industry packing,artificial leather, hose and shoe-making material, etc.

*SG-4 is used in producing membranelle for industrial andcivil use, tube and pipes

*SG-5 is used in producing transparent products sectionbar, hard tube and decorative materials,such

as Rigid plate, gramophone record, valueand welding rod, PVC pipes, PVC windows, doors ,etc

*SG-6 is used in producing clear foil, hard board andwelding rod

*SG-7, SG-8 is used in producing clear foil, hardinjection molding.Good hardness and high strength,mainlyused for tubes and pipes

Packaging

(1) Packing : 25kg net/pp bag, or kraft paper bag .

(2) Loading quantity : 680Bags/20′container, 17MT/20′container .

(3) Loading quantity : 1000Bags/40′container, 25MT/40′container .