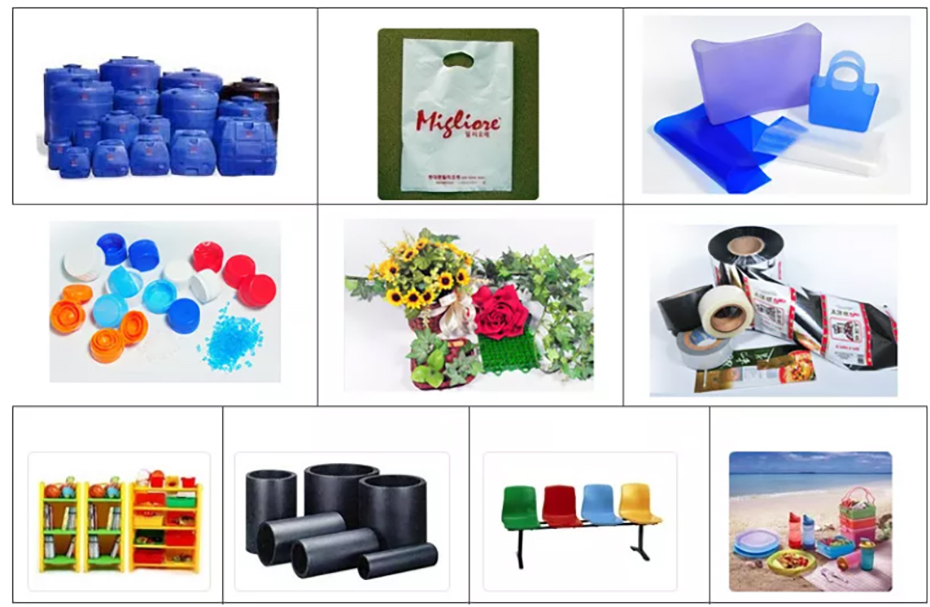

PP resin for packaging

PP resin for packaging,

medical, optical fiber cable, PP resin used for automobile,

Polypropylene is a synthetic resin made by polymerization of propylene (CH3—CH=CH2) with H2 as the molecular weight modifier. There are three stereomers of PP – isotactic, atactic and syndiotactic. PP contains no polar groups and has excellent electrical insulation properties. Its water absorption rate is less than 0.01%. PP is a semi-crystalline polymer with good chemical stability. It is stable to most chemical except strong oxidizers. Inorganic acid, alkali and salt solutions have almost no damaging effect on PP. PP has good heat resistance and low density. Its melting point is at around 165℃. It has high tensile strength and surface hardness and good environmental stress crack resistance. It can withstand 120℃ continuously.

Sinopec is the largest PP producer in China,Its PP capacity accounted for 45% of the country’s total capacity. The company currently has 29 PP plants by the continuous process (including those under construction). Technologies used by these units include Mitsui Chemical’s HYPOL process, Amoco’s gas phase process, Basell’s Spheripol and Spherizone process and Novolen’s gas phase process. With its strong scientific research capability, Sinopec has independently developed a second-generation loopprocess for PP production.

PP Features

1.The relative density is small, only 0.89-0.91, which is one of the lightest varieties in plastics.

2.good mechanical properties, in addition to impact resistance, other mechanical properties are better than polyethylene, molding processing performance is good.

3.It has high heat resistance and the continuous use temperature can reach 110-120 °C.

4.good chemical properties, almost no water absorption, and does not react with most chemicals.

5.the texture is pure, non-toxic.

6.electrical insulation is good.

Commonly used reference for PP grade

Application

Package

In 25kg bag, 16MT in one 20fcl without pallet or 26-28MT in one 40HQ without pallet or 700kg jumbo bag, 26-28MT in one 40HQ without pallet.

Polypropylene is non-toxic, odorless, tasteless milky white high crystallization polymer, is one of the lightest varieties of all plastics at present, good formability, products surface luster, heat resistance, corrosion resistance, products available steam disinfection is the outstanding advantages of polypropylene.

The main raw material of polypropylene is propylene, which is mainly made from naphtha, methanol and propane.

According to statistics, by the end of 2018, there were more than 160 propylene production enterprises in China, with an annual production capacity of about 32.3 million tons and annual output of about 27.1 million tons, a year-on-year growth of about 2.26%.

The price of propylene is affected not only by the price of crude oil, methanol, propane, but also by the market supply and demand relationship.

This kind of chemical raw material widely used in plastic weaving, packaging, automobile, medical, optical fiber cable and other fields, in the new industrial development, upgrading, there will be new requirements.

With the continuous development of our economy, the plastic processing industry presents a new demand trend of “functionalization”, “lightweight” and “micro-molding”, which drives the stable growth of the demand for thin-wall injection molding, high impact copolymerization, fiber and other polypropylene products.