Polyvinyl chloride resin QS-1000F

Polyvinyl chloride resin is a very widely used plastic material, can be divided into soft PVC and hard PVC. The product is usually white and powdery. According to different uses can be added to different additives, PVC plastic can present different physical and mechanical properties. A variety of hard, soft and transparent products can be made by adding appropriate plasticizer in PVC resin. Characteristics of the product is easy to forming, through extrusion, injection molding, calendering, blow molding, pressing, casting and thermoforming molding process for processing, can be made high strength and hardness of hard products such as pipe, pipes, doors and Windows, etc. Different profiles and package material, also can join plasticizer is made very soft products such as thin film, package materials, wire and cable, floor, synthetic leather, etc.

Grade QS-1000F is used to produce flexible film sheet, pressed material, piping molding-die tools, wire and cable insulation material, etc..

Parameters

| Grade | PVC QS-1000F | Remarks | ||

| Item | Guarantee value | Test method | ||

| Average polymerization degree | 950-1050 | GB/T 5761,Appendix A | K value 65-67 | |

| Apparent density, g/ml | 0.49 | Q/SH3055.77-2006, Appendix B | ||

| Volatiles content (water included), %, ≤ | 0.30 | Q/SH3055.77-2006, Appendix C | ||

| Plasticiser absorption of 100g resin, g, ≥ | 24 | Q/SH3055.77-2006, Appendix D | ||

| VCM residue, mg/kg ≤ | ≥5 | GB/T 4615-1987 | ||

| Screenings % | 2.0 | 2.0 |

Method 1: GB/T 5761, Appendix B Method 2: Q/SH3055.77-2006,Appendix A |

|

| 95 | 95 | |||

| Fisheye number, No./400cm2, ≤ | 20 | Q/SH3055.77-2006, Appendix E | ||

| Number of impurity particles, No., ≤ | 16 | GB/T 9348-1988 | ||

| Whiteness (160ºC, 10 minutes later), %,≥ | 80 | GB/T 15595-95 | ||

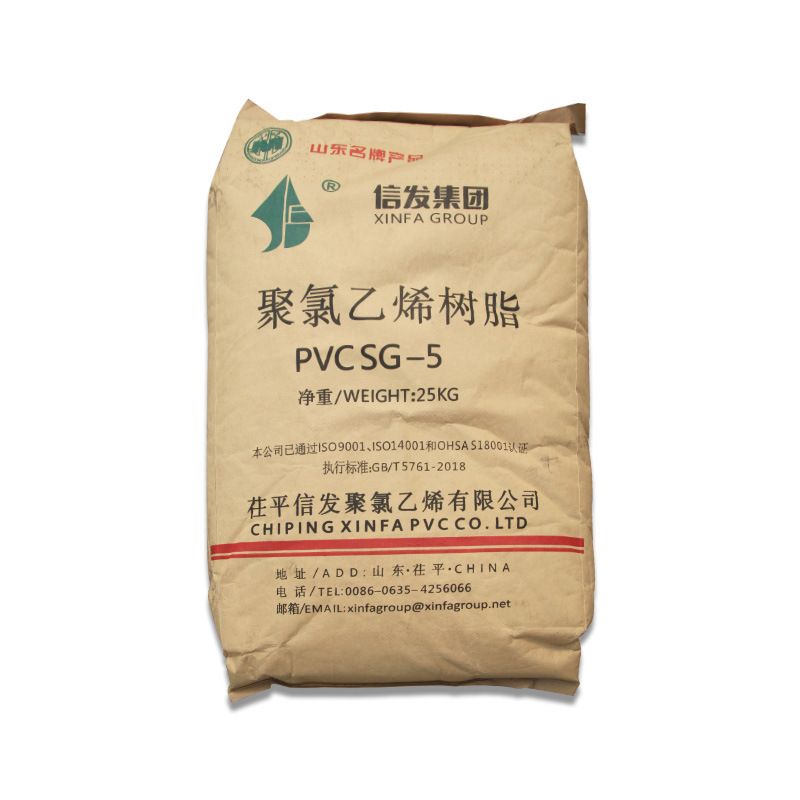

Packaging

(1) Packing : 25kg net/pp bag, or kraft paper bag .

(2) Loading quantity : 680Bags/20'container, 17MT/20'container .

(3) Loading quantity : 1000Bags/40'container, 25MT/40'container .