polypropylene for non-woven fabric

polypropylene for non-woven fabric,

PP Resin, PP resin for BOPP industry, PP resin for Injection molding industry,

Polypropylene is a synthetic resin made by polymerization of propylene (CH3—CH=CH2) with H2 as the molecular weight modifier. There are three stereomers of PP – isotactic, atactic and syndiotactic. PP contains no polar groups and has excellent electrical insulation properties. Its water absorption rate is less than 0.01%. PP is a semi-crystalline polymer with good chemical stability. It is stable to most chemical except strong oxidizers. Inorganic acid, alkali and salt solutions have almost no damaging effect on PP. PP has good heat resistance and low density. Its melting point is at around 165℃. It has high tensile strength and surface hardness and good environmental stress crack resistance. It can withstand 120℃ continuously.

Sinopec is the largest PP producer in China,Its PP capacity accounted for 45% of the country’s total capacity. The company currently has 29 PP plants by the continuous process (including those under construction). Technologies used by these units include Mitsui Chemical’s HYPOL process, Amoco’s gas phase process, Basell’s Spheripol and Spherizone process and Novolen’s gas phase process. With its strong scientific research capability, Sinopec has independently developed a second-generation loopprocess for PP production.

PP Features

1.The relative density is small, only 0.89-0.91, which is one of the lightest varieties in plastics.

2.good mechanical properties, in addition to impact resistance, other mechanical properties are better than polyethylene, molding processing performance is good.

3.It has high heat resistance and the continuous use temperature can reach 110-120 °C.

4.good chemical properties, almost no water absorption, and does not react with most chemicals.

5.the texture is pure, non-toxic.

6.electrical insulation is good.

Commonly used reference for PP grade

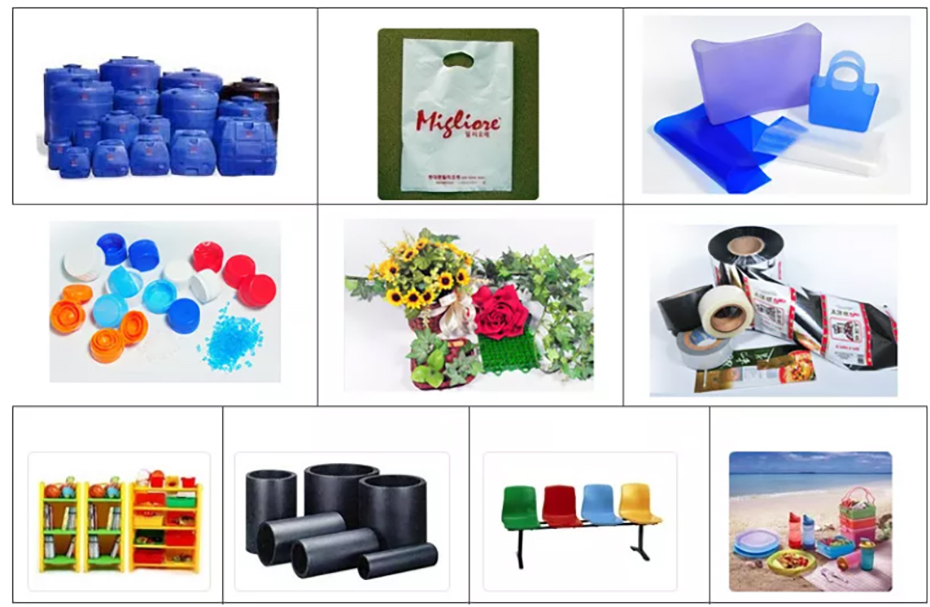

Application

Package

In 25kg bag, 16MT in one 20fcl without pallet or 26-28MT in one 40HQ without pallet or 700kg jumbo bag, 26-28MT in one 40HQ without pallet.

This week polypropylene downstream purchase intention decreased, factories have holidays, the overall construction significantly lower. As a whole, the domestic polypropylene downstream industry (including plastic knitting, injection molding, BOPP, PP non-woven fabric) overall operating rate fell by 14.7% to 36.2%. The rate of plastic knitting decreased by 9.5% to 34%; Injection molding rate down 17% to 32%; BOPP starts fell 2.8% to 60.1%; Non-woven starts fell 29.8% to 18.5%.

From the point of view of the demand side, this week’s plastic knitting enterprise operating rate is significantly lower than last week, down 13% year-on-year. At the end of the year, most enterprises have entered the holiday, the order situation of enterprises decreased significantly, some enterprises sporadic orders, the enthusiasm of enterprises to replenish raw materials decreased, mainly digest finished product inventory, the overall trading atmosphere of the market was cold; In terms of BOPP industry, the order days of sample enterprises this week are 7.89% compared with the previous period. As the overall demand of BOPP is not as good as in previous years, downstream and traders are on holiday in advance, and the overall trading atmosphere of the market is getting lighter as the Spring Festival approaches. Most of the membrane enterprises have placed orders in advance, and most of the membrane enterprises are working normally at the present stage, with limited follow-up of new orders. Injection molding industry starts to decline sharply, factories have holidays, the industry starts to decline obviously; Non-woven fabric industry within the week to start a significant correction, this week’s order days compared to last week -3.5 days, downstream orders showed a downward trend. PP non-woven fabric enterprises have entered the holiday, the new business transactions are very small. In general, affected by the Spring Festival holiday, the overall downstream construction fell sharply, before the holiday boosted by futures, stock performance improved, supporting polypropylene market trend relatively strong.

In the long run, polypropylene supply and demand fundamental game is still obvious. After the holiday, there is an expectation of stockpiling in the market. In addition, in the plan of new production capacity, Guangdong Petrochemical is expected to release materials during the holiday, and the market supply pressure increases significantly. In terms of demand, the downstream work resumption schedule after the holiday is the main concern of the market. It is suggested that operators pay close attention to the downstream work resumption schedule.