LDPE film grade

LDPE film grade,

LDPE for agricultural film, LDPE for packaging film,

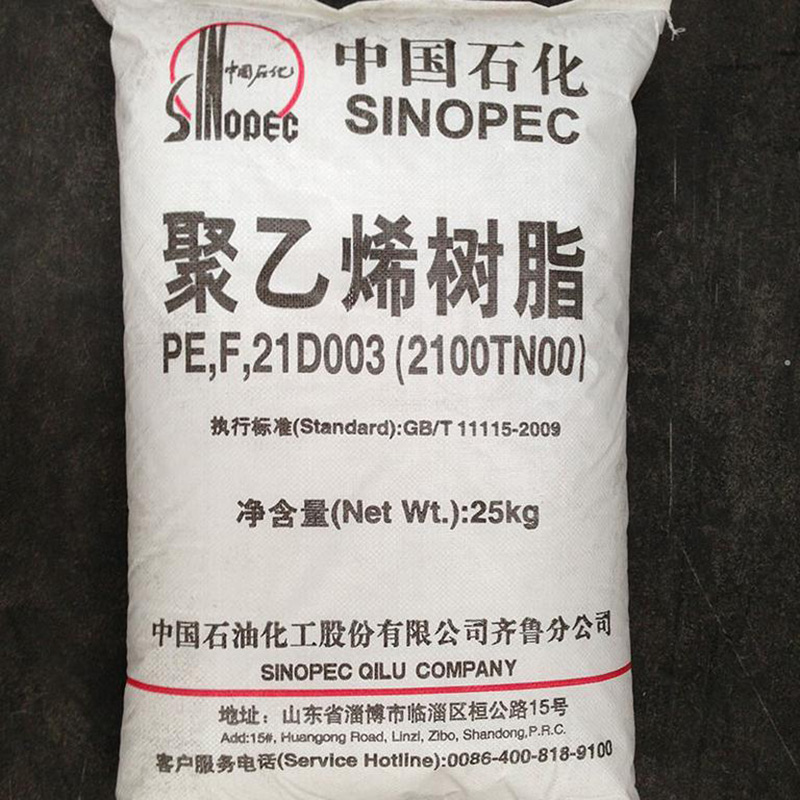

Low density polyethylene (LDPE), also known as high pressure polyethylene, is a white resin with a waxy texture, and its molecular structure is a nonlinear structure with a large number of long branched chains. Compared with medium density, high density polyethylene, LDPE crystallinity, softening point is lower, softness, elongation, electrical insulation and transparency is better, higher impact strength, it is suitable for thermoplastic forming processing of various forming process, forming processability is good.LDPE is mainly used for film products, but also for injection molding products, medical instruments, drugs and food packaging materials, blow molding hollow molding products, in agriculture, packaging industry, electronic and electrical engineering, mechanical equipment, automobile manufacturing and daily groceries and other aspects have a wide range of application prospects.

Feature

Application

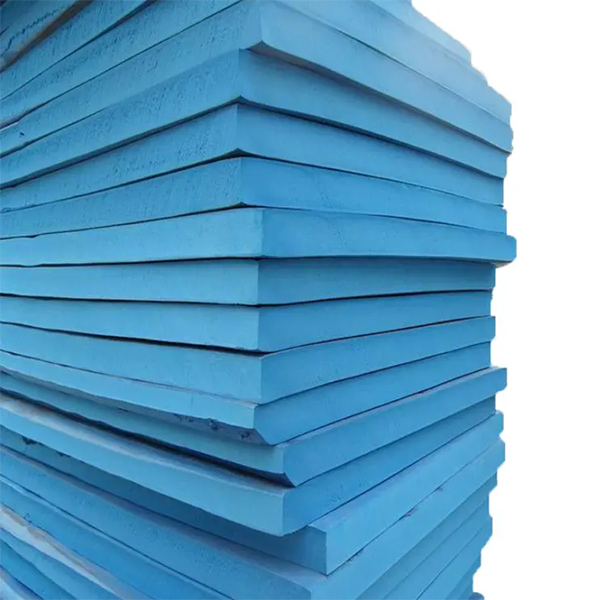

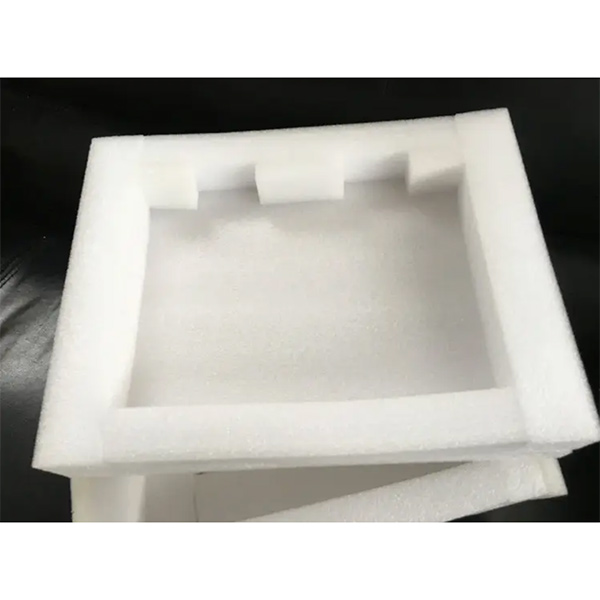

LDPE(2100TN00) is a good extrusion film material, mainly suitable for the production of light packaging film, agricultural mulch film, foam sheet material.

Parameters

Package, Storage and Transportation

Low-density polyethylene (LDPE) is a synthetic resin using a high pressure process via free radical polymerization of ethylene and is therefore also called "high-pressure polyethylene". Polyethylene LDPE has a high degree of short and long chain branching. It is one of the most simplest and common polymer.LDPE has high fluidity and good processability. It is suitable for being used in all types of thermoplastic processing processes, such as injection molding, extrusion molding, blow molding, rotomolding, coating,foaming, thermoforming, hot-jet welding and thermal welding.

Low-density polyethylene (LDPE) is a synthetic resin using a high pressure process via free radical polymerization of ethylene and is therefore also called "high-pressure polyethylene". Polyethylene LDPE has a high degree of short and long chain branching. It is one of the most simplest and common polymer.LDPE has high fluidity and good processability. It is suitable for being used in all types of thermoplastic processing processes, such as injection molding, extrusion molding, blow molding, rotomolding, coating,foaming, thermoforming, hot-jet welding and thermal welding.

it is mainly used in agricultural film industry,packaging film, medicine and food, packaging film, machinery parts, daily necessities, building materials, insulation coating of wire and cable and synthetic paper.