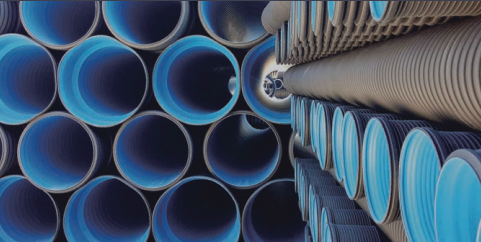

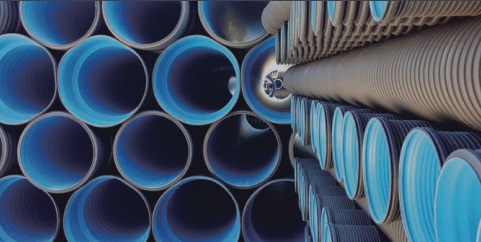

HDPE resin for double-wall corrugated pipe

HDPE resin for double-wall corrugated pipe,

HDPE resin for bellow, HDPE resin for double-wall bellows,

Due to the excellent performance of HDPE double-wall corrugated pipe, with the rapid development of society, it has gradually replaced the traditional pipe, bringing greater convenience to people’s life. This is because HDPE double-wall corrugated pipe is safer and more convenient than traditional steel pipe and concrete pipe in many aspects, and it is also welcomed by construction projects and is more and more widely used in various pipeline projects.

Today, let’s explain in detail what advantages HDPE double-wall bellows have?

1. HDPE double-wall corrugated pipe has strong compressive resistance. hdpe double-wall bellows have greater compressive strength than traditional bellows under the same pressure conditions. Due to its unique shape construction, its outer wall is corrugated, which can increase the ring stiffness of the pipe, giving it strong resistance to external pressure.

2, HDPE double-wall corrugated pipe has a high cost performance. Under the same load, HDPE double-wall corrugated pipe only needs to meet the requirements of thinner pipe wall, only the raw materials of other pipes can be used, compared with the cost of engineering cost savings. This is one of the reasons why many projects today choose it.

3, HDPE double-wall bellows construction speed is fast. Because of the thin wall of HDPE double-wall bellows, in the construction process, whether it is loading and unloading or connection, it is more convenient than the traditional pipeline, and the later maintenance is simple. If it is in a harsh built environment, it can show the advantages of HDPE double-walled bellows.

These are the properties of HDPE double-walled bellows, because it is a chemical for the production of plastic pipe, has good flexibility, and environmental properties, and therefore, can be widely used in pipeline engineering.

HDPE pipe grade has broad or bimodal distribution of molecular weight. It has strong creep resistance and good balance of rigidity and toughness. It is very durable and has low sag when being processed. Pipes produced using this resin have good strength, rigidity and impact resistance and excellent property of SCG and RCP.

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air. During transportation, the material should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

Application

HDPE pipe grade can be used in the production of pressure pipes, such as pressurized water pipes, fuel gas pipelines and other industrial pipes. It can also be used for making non-pressure pipes such as double-wall corrugated pipes, hollow-wall winding pipes, silicon-core pipes, agricultural irrigation pipes and aluminumplastics compound pipes. In addition, through reactive extrusion (silane cross-linking), it can be used for producing crosslinked polyethylene pipes (PEX) for supplying cold and hot water.