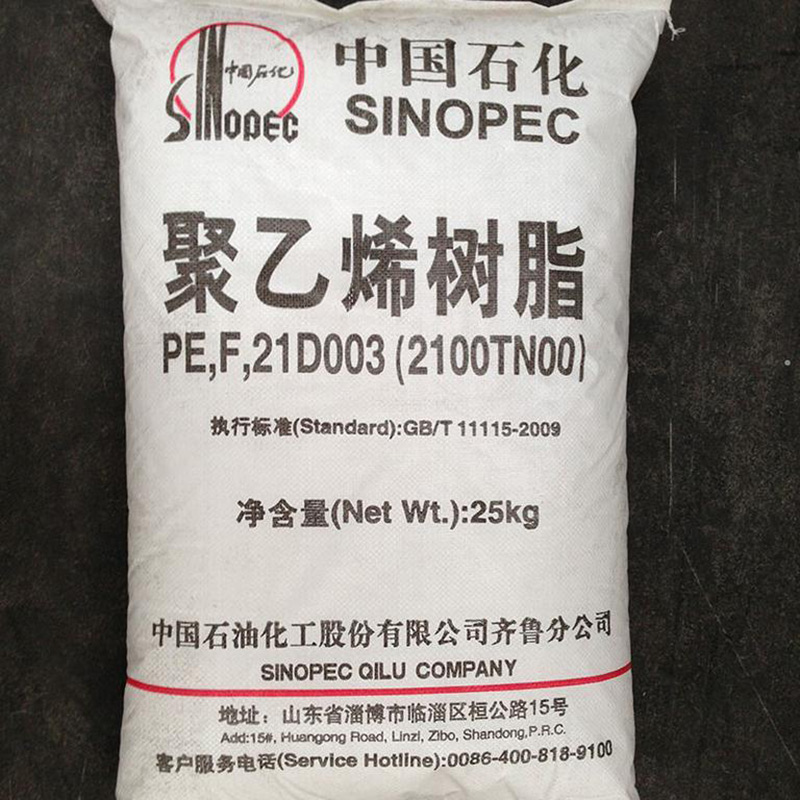

HDPE pipe grade

HDPE pipe grade,

HDPE for pipe and fitting, HDPE for pipe production, HDPE pipe raw material,

HDPE pipe grade has broad or bimodal distribution of molecular weight. It has strong creep resistance and good balance of rigidity and toughness. It is very durable and has low sag when being processed. Pipes produced using this resin have good strength, rigidity and impact resistance and excellent property of SCG and RCP.

PE as a material is very tough and inert material, hence there are no effects of surrounding aggressive soil conditions. PE pipes are light in weight, easy to handle, transport & install. The performance of PE pipes during its entire lifetime remains the same, no scale build-up, no-erosion, no-corrosion, no effect of sunlight/UV rays if installed above ground exposed to sun. PE pipes & fittings are available up to 2500mm outer diameter. PE pipes and fittings are available as per all Indian and all International Standards in PE 63, PE80 and PE100 material grade.

The water, chemical or any type of fluids are conveyed through the network of interconnected PE pipes and fittings which are 100% leak-proof, and the life of PE Pipes and fittings is at least 100 years. The Life Cycle Analysis shows PE pipes totally eco-friendly by its low energy consumption in fluid conveyance pipelines. Because of a smoother internal surface, PE pipes need lesser electricity for pumping the water. In addition to this the major advantage of PE pipes is its flexibility & leak-proof joints. Because PE pipes are flexible in nature, PE pipes easily take the shape of ground terrain inside industrial area or take the shape of trench profile which directly leads to saving in pipes accessories life bends, elbows and trenching cost. PE Pipes are available in required lengths up to 12m straight lengths.

The water conveyed through Jain PE pipes is fit for human consumption and as PE pipes are inert in nature any type of fluid, chemical, effluent can be conveyed. PE as a material is very tough and inert material, hence there are no effects of surrounding aggressive soil conditions or contents of fluid conveyed. PE pipes are light in weight, easy to handle, transport & install. The performance of PE pipes during its entire lifetime remains the same, no scale build-up, no-erosion, no-corrosion, no effect of sunlight/UV rays if installed above ground exposed to sun. PE pipes & fittings are available up to 2500mm outer diameter.

Application

HDPE pipe grade can be used in the production of pressure pipes, such as pressurized water pipes, fuel gas pipelines and other industrial pipes. It can also be used for making non-pressure pipes such as double-wall corrugated pipes, hollow-wall winding pipes, silicon-core pipes, agricultural irrigation pipes and aluminumplastics compound pipes. In addition, through reactive extrusion (silane cross-linking), it can be used for producing crosslinked polyethylene pipes (PEX) for supplying cold and hot water.