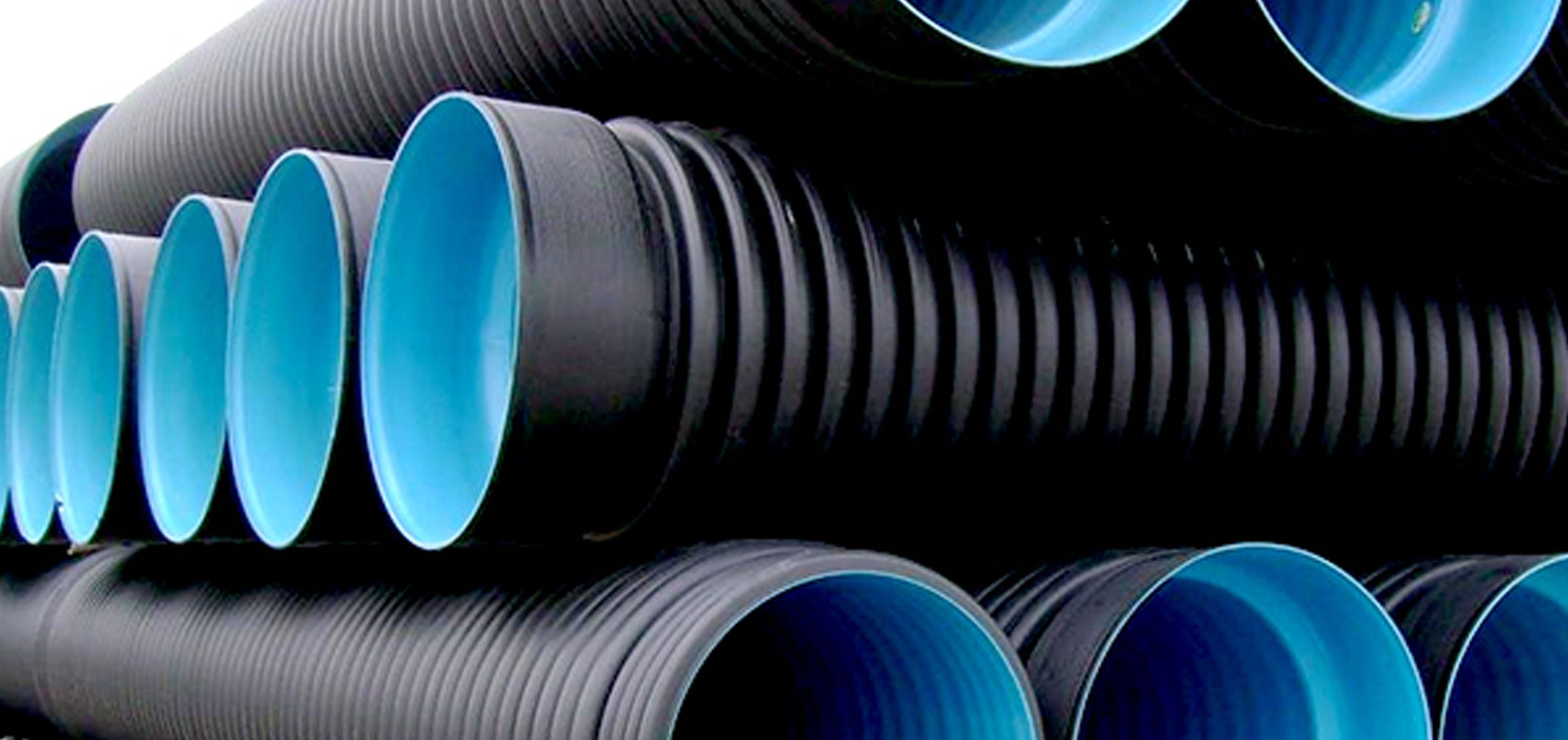

HDPE double wall corrugated pipe raw material

HDPE double wall corrugated pipe raw material,

HDPE for double wall corrugated pipe production, Which kind of HDPE resin is used for double wall corrugated pipe,

HDPE double wall corrugated pipe raw material

1. Composition of raw materials: The raw materials of PE double-wall bellows are generally composed of polyethylene, enhanced master materials and pigments. If the raw material is wet, in order to improve production efficiency, appropriate defoamer can be added.

2, the performance requirements of raw materials: how to produce a low cost, high quality bellows, largely depends on the choice of raw materials and formula collocation.

The general requirements for the performance of polyethylene (PE) include melt flow rate (MFR), oxidation induction time (OIT) and density. The size of melt flow rate reflects the size of molecular weight. Generally speaking, the material with higher melt flow rate is conducive to processing and forming, and can improve the

production efficiency. However, it can not be too large, which has a greater impact on the ring stiffness. It is appropriate to choose between 0.8-1.5g/10min(190℃, 5kg). Oxidation induction time determines the time of oxidation damage. For the bellows requiring 50 years of use, controlling the oxidation induction time of raw materials is the key to ensure the service life of 50 years. It is clearly stipulated in GB/T19472.1-2004 that the oxidation induction time of the raw material of bellows should be ≥20min (200℃). For medium and high density polyethylene, its properties can be adjusted by changing the density. Because we know that relatively low density polyethylene can prolong its brittle failure time.

production efficiency. However, it can not be too large, which has a greater impact on the ring stiffness. It is appropriate to choose between 0.8-1.5g/10min(190℃, 5kg). Oxidation induction time determines the time of oxidation damage. For the bellows requiring 50 years of use, controlling the oxidation induction time of raw materials is the key to ensure the service life of 50 years. It is clearly stipulated in GB/T19472.1-2004 that the oxidation induction time of the raw material of bellows should be ≥20min (200℃). For medium and high density polyethylene, its properties can be adjusted by changing the density. Because we know that relatively low density polyethylene can prolong its brittle failure time.

HDPE pipe grade has broad or bimodal distribution of molecular weight. It has strong creep resistance and good balance of rigidity and toughness. It is very durable and has low sag when being processed. Pipes produced using this resin have good strength, rigidity and impact resistance and excellent property of SCG and RCP.

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air. During transportation, the material should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

Application

HDPE pipe grade can be used in the production of pressure pipes, such as pressurized water pipes, fuel gas pipelines and other industrial pipes. It can also be used for making non-pressure pipes such as double-wall corrugated pipes, hollow-wall winding pipes, silicon-core pipes, agricultural irrigation pipes and aluminumplastics compound pipes. In addition, through reactive extrusion (silane cross-linking), it can be used for producing crosslinked polyethylene pipes (PEX) for supplying cold and hot water.