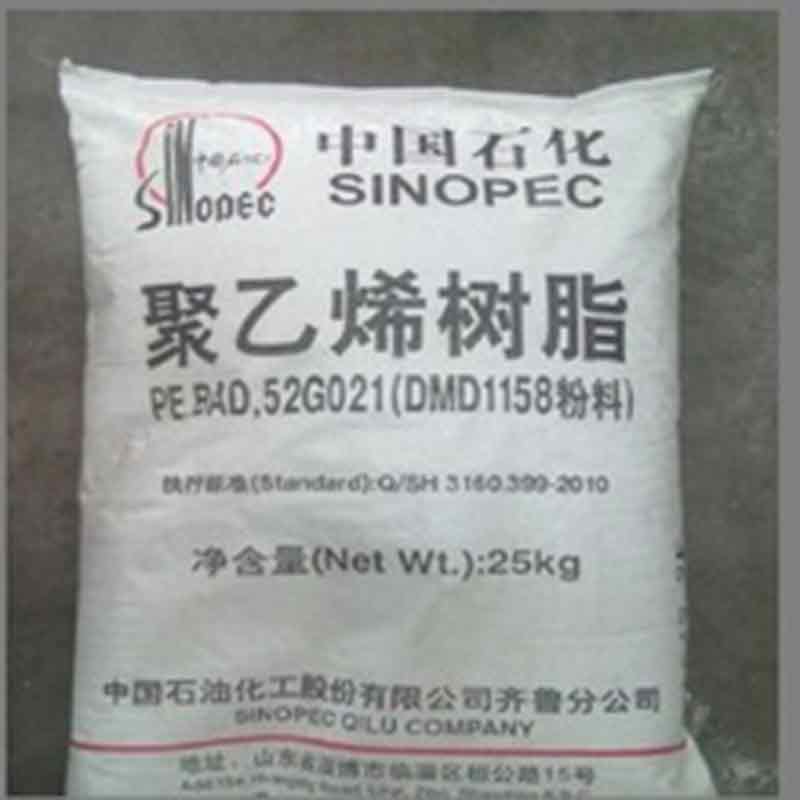

HDPE 1158 for IBC Barrel

HDPE 1158 for IBC Barrel,

HDPE for IBC barrel, HDPE for IBC containe

The IBC(Intermediate Bulk Containers )tank is a medium-sized bulk container. It is one of the necessary tools for the transportation of liquid products in modern storage. The IBC barrel is mainly a hollow blow molding process. After the raw material is extruded, the plasticized parison is blown in the mold. Expand into a product, then cool, and take out the product.

220L closed L ring drum and ton packing drum (IBC drum).

(1) 220L closed l-ring VAT was first jointly developed by Mauser company and BASF Company in 1977. The barrel is composed of an extrusion blow molded closed barrel body and an injection molded L ring. L ring is set in the upper and lower end grooves of the barrel body, which can strengthen the edges at both ends of the barrel and make the barrel easy to load and unload. The diameter of the drum is 598mm, the height is 900mm, the weight is 9.5-10.5kg, and the standard color is blue. The plastic VAT has the following advantages:

① Can ensure the safety of transportation, suitable for road, railway, sea and air transportation;

(2) easy to use, lifting, stacking, rolling;

(3) Good international versatility, has been recognized by many countries and international organizations;

(4) After cleaning can be reused, the average is 15~30 times, iron bucket is only 4~6 times;

⑤ Good dimensional stability, good earthquake resistance, not easy to break, small quality; Good chemical resistance, no rust, will not pollute the containing chemicals;

At present, the HMWHDPE that can be used for blow molding L ring VAT mainly include Lupolen 5261 of Germany BASF Company, TR550 TR571 of America Philips Company, DMDY1158 of Qilu Petrochemical Company and 5420GA of petrochina Dushanzi Petrochemical Company.

(2) Container also called IBC, IBC container, thousand liter barrel, is the international general medium-sized bulk container, using high molecular weight high density polyethylene (HMWHDPE), in accordance with the international container ⅱ, ⅲ class dangerous goods liquid production and manufacturing standards, products are suitable for storage and transportation, can contain all kinds of liquid and powder, Widely used in chemical fertilizer, pesticide, daily chemical, paper making, printing and dyeing, coating, brewing, intermediates, beverage and other industries. Especially suitable for road, rail and sea transportation, more suitable for international standard container export.

High density polyethylene resin products are granule or powder, no mechanical impurities. Thermoplastic elastomers have the physical and mechanical properties of vulcanized rubber and the processing properties of soft plastics. Because rubber is no longer thermally-vulcanized, it can be easily made into a final product using simple plastic processing machinery. Its characteristics, the rubber industry production process shortened l/4, saving energy 25% ~ 40%, improve efficiency 10 ~ 20 times, can be called the rubber industry another material and technology revolution. The two main methods of manufacturing and processing thermoplastic elastomers are extrusion and injection molding, which is rarely used. Thermoplastic elastomers are manufactured by injection molding, which is fast and economical. The injection molding methods and equipment used for general thermoplastics are applicable to thermoplastic elastomers. Thermoplastic elastomers can also be processed by blow molding, hot forming, and hot welding.

Application

DMD1158 powder, butene copolymerization product, special material for large hollow vessel, with good toughness, resistance to environmental stress cracking and good processability. Resin storage warehouse environment should be kept ventilated, dry, away from fire and direct sunlight. Open air environment should not be stacked for a long time. During transportation, materials shall not be exposed to strong light or heavy rain, and shall not be transported together with sand, soil, scrap metal, coal or glass. It is strictly prohibited to transport with toxic, corrosive and flammable substances.