In the process of PVC production, due to the production process control index formula parameters and other factors, the same type of PVC produced by different companies (SG5 type for example) in the performance is different For PVC processing enterprises, are often at the same time the use of multiple products, and different company in the production of PVC in the performance differences (even minor), need processing enterprises in the process of production for proper adjustment formula, PVC, or else the same formula for different companies may appear in processing production quality problem Therefore, for PVC processing enterprises, understand the performance parameters of each PVC, can be designed according to the performance characteristics of its products, to avoid blind debugging caused by the waste of resources For PVC production enterprises, to understand the company production of PVC with other companies in the performance differences, can highlight their strengths, compensate for their own weakness, make the product more market competition conditions, the author only for domestic A B c D E manufacturers of PVC on apparent viscosity of the melt apparent performance testing In the experiment, the author completely in accordance with the principle of seeking truth from facts, fair and objective testing, according to the basic theory of PVC processing, the performance of the product indicators are compared.

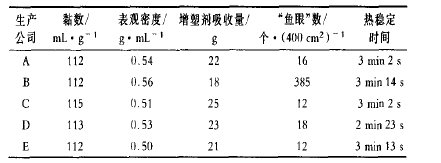

(1) PVC produced by Factory C has the highest viscosity. The higher the viscosity, the more difficult PVC resin plasticizing, the more difficult processing; The lowest viscosity is A, B, E factory produced PVC, viscosity is low, PVC resin is easy to plasticize, easier to process.

(2) The apparent density of PVC produced by factory B is the largest, and that produced by factory E is the smallest. In the process of PVC resin processing, the smaller the PVC resin particles (that is, the greater the apparent density), the more delicate the products made and the “fish eye” number is less, easy to process.

(3) The amount of plasticizer absorption was the largest in PVC produced by factory C and the smallest in PVC produced by factory B. The greater the amount of plasticizer absorption, PVC resin in the mixing process is easier to absorb plasticizer, lubricant and other processing additives, the quality of the mixture is good, its processing melting performance is also better.

(4) The number of “fish eyes” produced by B factory is the most PVC. ”Fisheye” is the essence of polymerization process due to improper conditions and the formation of a small amount of molecular structure of polymer PVC, which is difficult to plasticize in the process of PVC processing, has a great impact on product quality, so the less the number of “fisheye” the better.

(5) From the perspective of thermal stabilization time, PVC produced by factory B has the longest thermal stabilization time, while PVC produced by factory D has the shortest thermal stabilization time. The thermal stability of resin directly affects the processing of products, especially for hard products. In order to prevent PVC decomposition in the processing process, prolong the processing time, must adjust the dosage of stabilizer in the formula according to its stability.

Post time: Aug-08-2022